Understanding the Basics of Ceramic Firing

Introduction to Ceramic Firing

Ceramic firing is a pivotal process in the creation of ceramic art and pottery. This transformative procedure involves exposing clay objects to high temperatures, causing chemical and physical changes that solidify the clay into a permanent shape. Understanding the basics of ceramic firing is essential for anyone interested in ceramics, whether they are a novice looking to get started or a seasoned professional aiming to refine their craft.

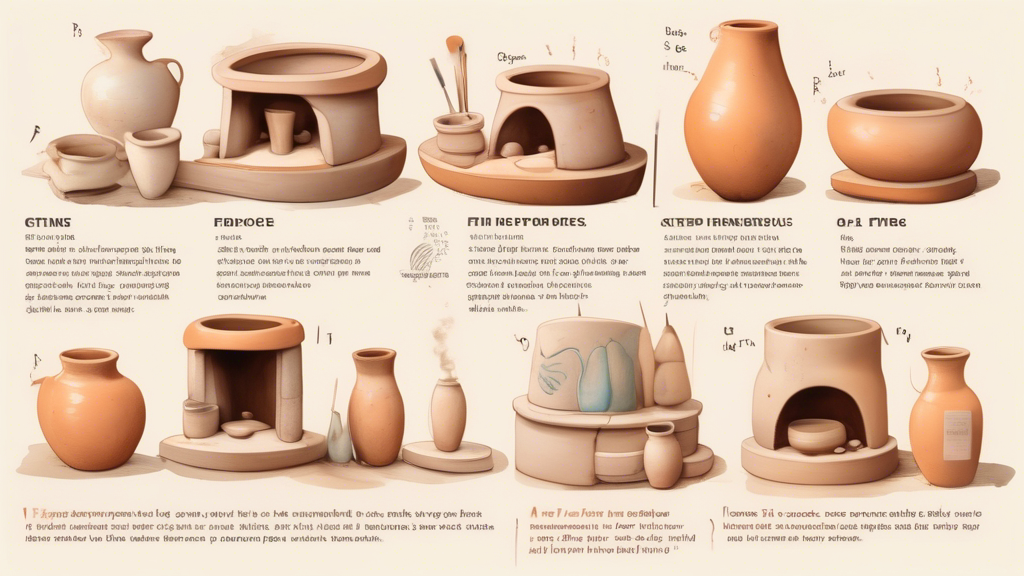

The Stages of Ceramic Firing

Ceramic firing is not a one-size-fits-all process; it consists of several stages, each critical to achieving the final product's durability, texture, and appearance. These stages are generally categorized as bisque firing and glaze firing, although there may be additional firings depending on the specific techniques and finishes being applied.

Bisque Firing

Bisque firing represents the initial firing stage, designed to turn greenware (unfired clay objects) into bisqueware. This process usually occurs at temperatures ranging from 1000°C to 1100°C (1832°F to 2012°F). The primary goal of bisque firing is to eliminate all moisture, organic materials, and chemical water from the clay, making it stronger and less fragile. This stage also prepares the ceramic piece for glazing, as bisqueware is more absorbent, allowing it to take on glaze more effectively.

Glaze Firing

After bisque firing and glazing, the ceramic piece undergoes glaze firing. This phase melts the glaze applied to the bisqueware, creating a glassy surface that is both decorative and functional. Glaze firing temperatures can vary widely, depending on the type of glaze used, but they typically range from 1060°C to 1300°C (1940°F to 2372°F). This stage not only enhances the piece's aesthetic appeal but also seals the surface, making it waterproof and more durable.

Types of Kilns

The type of kiln used can significantly impact the firing process and the final outcome of the ceramic work. Kilns can be fueled by wood, gas, electricity, or other energy sources, and each type has its own set of advantages and considerations.

Electric Kilns

Electric kilns are popular in contemporary ceramics because of their ease of use and control. They provide a clean and consistent heat source, making them ideal for both bisque and glaze firings. However, they may lack the atmospheric effects produced by alternative fuel sources.

Gas Kilns

Gas kilns are favored for their ability to create unique atmospheric effects, such as reduction, which can significantly impact the colors and textures of the final ceramic pieces. They require more expertise to operate than electric kilns and can have higher operating costs.

Wood Kilns

Wood kilns offer a traditional and organic approach to firing, known for the unique, natural effects they impart on ceramics. They can produce striking results but require considerable time and effort to manage the firing process.

Conclusion

Understanding the basics of ceramic firing is crucial for anyone looking to explore or advance in the world of ceramics. Each stage of firing, from bisque to glaze firing, plays a significant role in achieving the desired properties and aesthetics of the final ceramic piece. Additionally, the choice of kiln can greatly influence the outcome, offering a range of possibilities from uniform surfaces with electric kilns to the unique, unpredictable effects possible with gas or wood-fired kilns. With a solid grasp of these fundamentals, individuals can experiment with confidence and creativity in their ceramic endeavors.

Click this link to check out our ceramic artwork!